Get Your Hands On Our Custom Cellophane Now

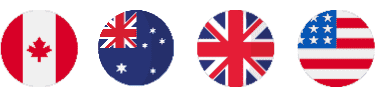

Are you searching for the perfect packaging solution that combines elegance, versatility, and protection? Look no further! Our custom cellophane bags wholesale are design to meet your packaging needs and leave a lasting impression on your customers.

With their transparent and glossy appearance, these bags allow your products to shine while providing a protective barrier against moisture, dirt, and damage.

Unveiling The Beauty Of Customization For Wholesale Cellophane Bags

We understand the importance of showcasing your products in a way that captures attention and reflects your brand’s unique identity. That’s why we offer customizable options for our wholesale cellophane bags. From choosing the perfect size and shape to adding your own design or logo, our team will work closely with you to create packaging that truly stands out.

Whether you’re packaging cosmetics, handmade treats, or small gifts, our cellophane bags will elevate your products to the next level.

Protection You Can Rely On

Beyond aesthetics, our custom cellophane bags are design with product protection in mind. The cellophane material offers a strong and durable barrier against moisture, keeping your items safe and intact. Say goodbye to worries about spills, dust, or damage during transportation or display. With our cellophane bags, you can have peace of mind knowing that your products are safeguarded while still being beautifully showcased.

Exploring Printing Methods For Custom Printed Cellophane Bags

When it comes to creating visually appealing and eye-catching custom printed cellophane bags, the printing method you choose plays a significant role. At Packaging Mines, we offer various printing techniques that cater to different design requirements and budgets. Let’s explore some of the popular printing methods we utilize to bring your packaging ideas to life:

Offset Printing

Offset printing, also known as lithography, is a widely use printing method known for its high-quality results. It involves transferring ink from a metal plate to a rubber blanket, which is then pressed onto the packaging material.

Offset printing delivers precise and vibrant colors, sharp details, and consistent results. It is suitable for large production runs and offers excellent color accuracy, making it ideal for intricate designs, gradients, and photographic elements.

Digital Printing

Digital printing is a versatile and cost-effective printing method that is well-suited for shorter production runs and quick turnaround times. It involves directly transferring the digital artwork onto the packaging material using inkjet or laser technology.

Digital printing offers flexibility, allowing for easy customization, variable data printing, and shorter lead times. It is an excellent choice for small to medium-size batches, personalized packaging, and prototypes.

Flexographic Printing

Flexographic printing, also known as flexo printing, is a popular choice for packaging materials such as labels, bags, and corrugated boxes. It utilizes flexible relief plates and fast-drying inks to transfer the design onto the packaging material. Flexo printing is known for its efficiency, speed, and cost-effectiveness. It is suitable for high-volume production runs and can accommodate various substrates, including paper, film, and plastic.

Screen Printing

Screen printing is a versatile printing method that involves forcing ink through a fine mesh screen onto the packaging material. It is commonly use for bold, vibrant designs and special effects. Screen printing offers excellent ink opacity and the ability to print on various substrates, including glass, plastic, and metal. It is ideal for packaging that requires a tactile feel, metallic finishes, or raise textures. So, what are you waiting for?

Get your hands on Packaging Mines today!